Through material requisition process, an authorized user requests the inventory location for materials on behalf of the operational entity .

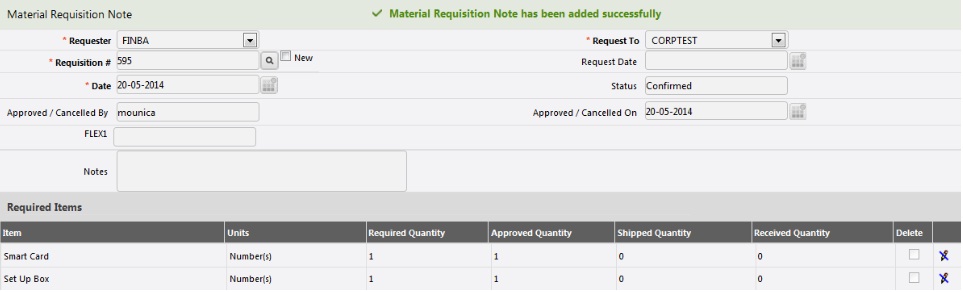

A request note called as Material Requisition Note (MQN) is initiated by the operational entity to request the inventory location for delivery of materials. A MQN usually includes the sourcing and purchasing agent names, requested dates, required item names, quantities and the reason for every requisition (like stocking up for anticipated business, for issue against current contracts etc.).

Following three different activities are involved in material requisition process:

A material request is generated when an operational entity requests the inventory location to supply the required items. The possible reason being shortage of stock at operational entity. In Billing & CRM solution, operational entity requests the items through Material Requisition Note screen.

Navigation: Inventory

& Logistics ![]() Material Requisition

Material Requisition

![]() Requisition Note

Requisition Note

In the Requestor drop-down, select the operational entity which is requesting for the material.

Select the New check box against the Requisition # box. By default, the check box is selected.

In the Inventory location drop-down, select the inventory location from which the operational entity is requesting the material.

Type or select required information in the provided fields.

In Required Items panel, click Add to add the required items.

In the Item drop-down, select the hardware item which you want to request.

In provided fields, type relevant information. You can request for multiple items in a single material requisition note.

Click Save to save the requisition note.

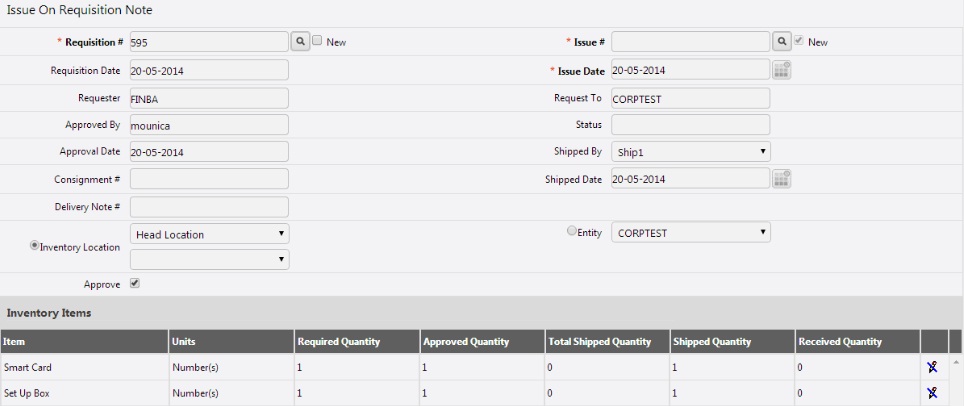

The material requested by the operational entity is issued by the inventory location. The inventory location may issue full stock requested by the operational entity or partial stock based on the stock available with the inventory location. Material is issued through Issue on Requisition screen.

Navigation:

Inventory & Logistics ![]() Material

Requisition

Material

Requisition ![]() Issue

Issue

In the Inventory Location drop-down, select the inventory location from which you want to issue the material.

Select the New check box against the Issue # box. By default, the check box is selected.

In the Requisition # box, type the requisition number which is generated in Generating material request step.

In

the Inventory Items panel, click ![]() against

the item. In Shipped Quantity, type the number of items you want to

issue.

against

the item. In Shipped Quantity, type the number of items you want to

issue.

Click

![]() to enter the quantities of item to be issued

under Shipped Quantity column. Repeat the process to issue multiple

items.

to enter the quantities of item to be issued

under Shipped Quantity column. Repeat the process to issue multiple

items.

Click the Serial Numbers button to capture serial numbers of the serialized items in Capture Serial Numbers pop up window.

Click Save in the main window to issue the hardware items.

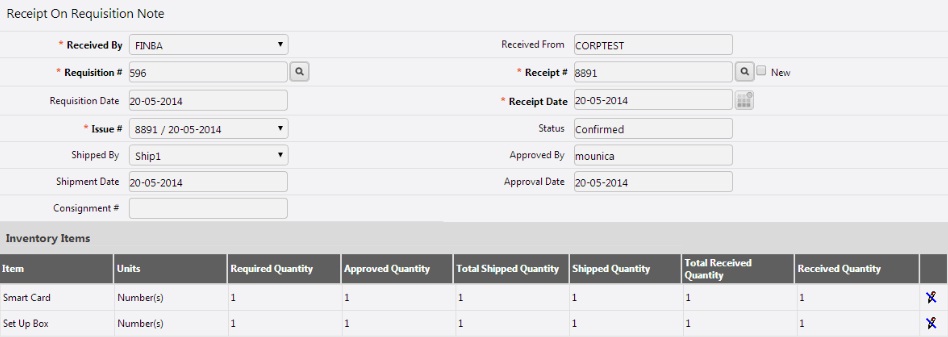

The operational entity receives the material issued by the inventory location. The receiving transaction is recorded through Material Receipt Note screen. Billing & CRM solution provisions you to generate the material receipt automatically and manually.

A material receipt is automatically generated by setting the profile option "Auto receive on Material Requisition" value to Yes. You can check for the Material Receipt Note in Material Receipt Note screen.

Navigation: Inventory

& Logistics ![]() Material Requisition

Material Requisition

![]() Receipt

Receipt

Clear New check box against Receipt # box.

You can see that a receipt number is already generated. Search for the receipt number and click the receipt number hyperlink.

The details pertaining to the material receipt note are displayed on the screen.

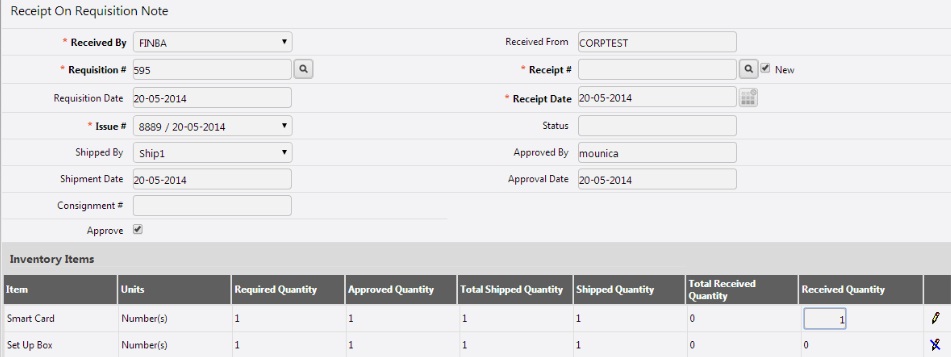

Material receipt is generated on receiving the material by the operational entity through Material Receipt Note screen.

Navigation: Inventory

& Logistics ![]() Material Requisition

Material Requisition

![]() Receipt

Receipt

In

Requisition # box, type the

requisition number. You can also click ![]() to browse

for a requisition number.

to browse

for a requisition number.

In Inventory Items panel, enter received quantity in provided box.

Click

![]() to update.

to update.

Click Serial Numbers to select serial numbers in One Time Sale Order Serial Numbers dialog box.

Select the check box against the serial numbers or select Check All to select all the serial numbers and click Save to save the selected serial numbers.

Click Save in the main page to generate a receipt note.

![]() Note:

Note:

Material Requisition Note is entered only by an authorized user at an inventory location who has privilege to receive material from the inventory locations.

Dealer location or distributor location is not considered as an inventory location and hence material can not be issued from the supplier to these locations.

4x to 5x Migration section is intended for the users who are migrating from 4x to 5x. This section compares the terminology and functionality of 5x application with 4x application.

4x |

5x |

Subscriber |

Customer |

Dealer or Business Entity |

Operational Entity |

Stock Point |

Inventory Location |

Serial Number |

Serial Number |

The following table compares the customer activation process flow in 5x and 4x.

4x |

5x |

Generating Material Requisition Note (MRN) Material is requested through Material Requisition Note screen. Note: Material is requested by a business entity from another business entity. Each business entity is mapped with a stock point. |

Generating Material Requisition Note (MQN) Material is requested through Material Requisition Note screen. Note: Material is requested by an operational entity from the Inventory Location. |

Issuing the requested material Material is issued through Material Issue screen. Note: The stock point from which the material is issued is provided in this screen |

Issuing the requested material Material is issued through Issue On Requisition Note screen. |

Receiving Material Material receipt note is not mandatory. |

Receiving Material Material is received by generating Material Receipt Note through Material Receipt Note screen. |